No products

Prices are tax excluded

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

View larger

View larger

Resi-Fix

New

Please view the 'Quantity Discounts' tab below to see our pricing for larger orders.

- More info

- Quantity Discounts

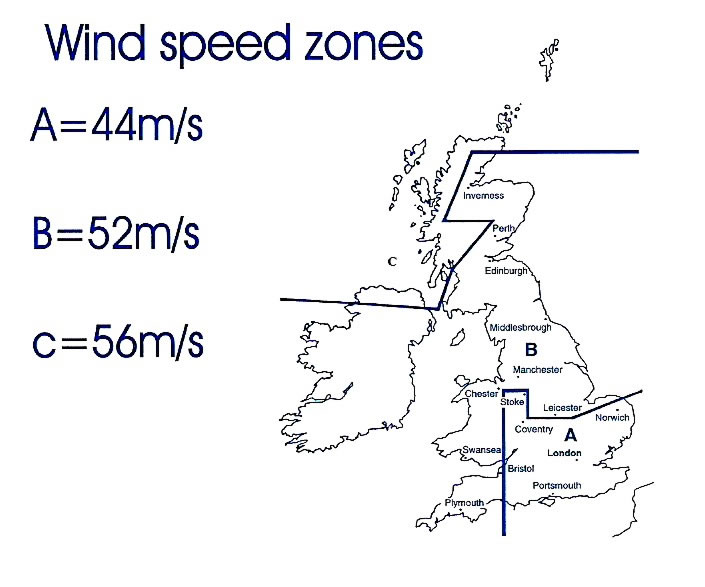

- Wind Zones

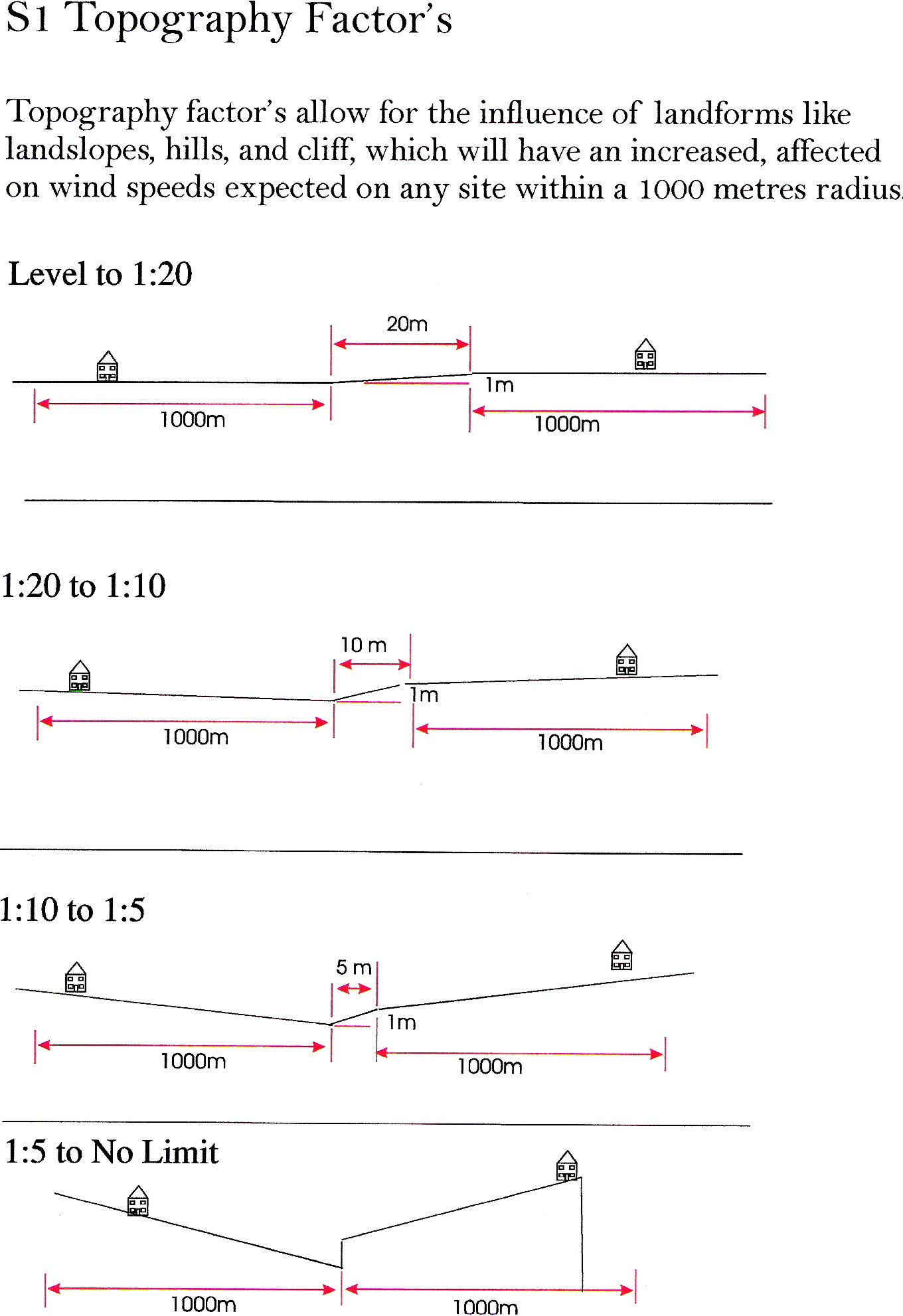

- Topography

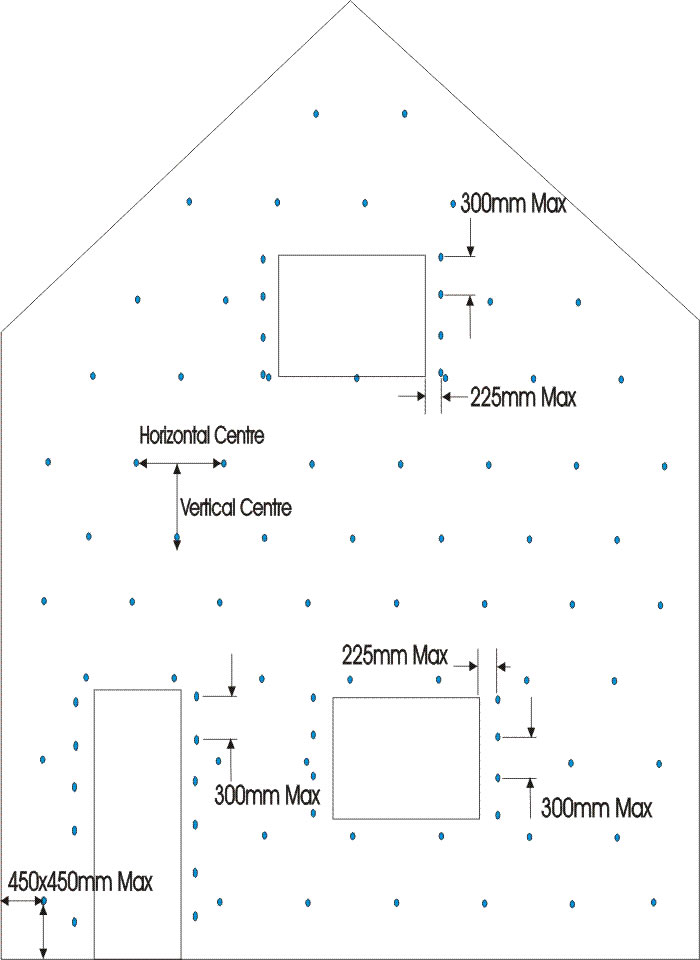

- Tie Densities

- Tie Selection

- Tie Spacing

- Installation

- Triset Resin

- PDF Download

- Related Posts

The Resi-Fix cavity wall tie replacement system, when a resin bond is required

in both inner and outer leafs of differing materials like, air-crete blocks, clay bricks,

stone, and concrete blocks, ideal for small one off jobs of about 30 to 200 ties.

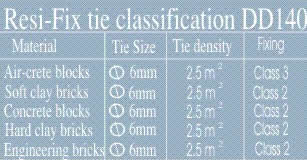

Resi-Fix Ties are manufactured out of 304 or 316 Stainless Steel and have been independently tested using a common range of building materials by the University of Portsmouth material testing department in accordance with BS 1243 and EN10088 They can be installed quickly and easily by drilling a clearance hole through the outer

leaf then 70mm into the inner leaf. After cleaning out the holes with an air pump, fill

the inner hole with resin and then insert Resi-Fix Tie and then fill outer hole with resin. The constant helix of Resi-Fix Ties gives multi water drips stopping water transfer across cavities. The low cross sectional area of Resi-Fix Ties gives good sound proofing qualities and allows lateral flexibility to over come any misalignment or seasonal thermal movement while still maintaining the required resistance to wind-loads.

Installation Procedure

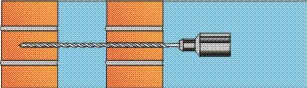

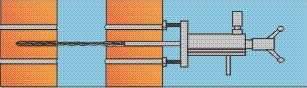

1. Drill clearance hole through the outer leaf and 70mm into the inner leaf.

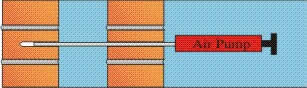

2. Clean both holes of any dust or debris.

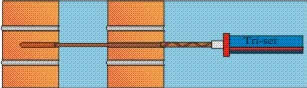

3. Fill inner hole with Tri-Set resin.

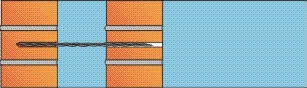

4. Insert Resi-Fix tie.

5. Load test Resi-Fix Tie

6. Fill clearance hole with Tri-Set Resin to bond tie to outer leaf.

| Size | Buy 10+ | Buy 20+ | Buy 100+ |

| 100 Resi Fix Ties 6mm x 170mm | £38.96 | £36.91 | £30.76 |

| 100 Resi Fix Ties 6mm x 195mm | £45.47 | £43.08 | £35.90 |

| 100 Resi Fix Ties 6mm x 220mm | £51.96 | £49.23 | £41.02 |

| 100 Resi Fix Ties 6mm x 245mm | £58.46 | £55.38 | £46.15 |

| 100 Resi Fix Ties 8mm x 195mm | £51.96 | £49.23 | £41.02 |

| 100 Resi Fix Ties 8mm x 220mm | £58.46 | £55.38 | £46.15 |

| 100 Resi Fix Ties 8mm x 245mm | £64.95 | £61.53 | £51.28 |

| 100 Resi Fix Ties 8mm x 270mm | £71.46 | £67.70 | £56.41 |

| 100 Resi Fix Ties 8mm x 295mm | £77.95 | £73.85 | £61.54 |

| S2 Ground roughness, building size and height above ground factor worse case class A, HEIGHT 15 METRES. | |

|

I |

Open country with no windbreaks and seafronts |

| II | Open country with scattered windbreaks |

| III | Suburban country with many wind breaks; small towns, out skirts of large cities |

| IV |

Urban surface with large and frequent obstructions, i.e. City centres |

|

Tie loads for different site conditions

|

||||||||||||

|

TIE DENSITY

|

Wind Zone A (44m/s)

|

Wind Zone B (52m/s)

|

Wind Zone C (56m/s)

|

|||||||||

|

2.47m2

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

|

Level to

1:20 |

-1000N

|

-940N

|

-730N

|

-520N

|

-1400N

|

-1320N

|

-1020N

|

-720N

|

-1620N

|

-1520N

|

-1180N

|

-840N

|

|

1:20 to

1:10 |

-1260N

|

-1180N

|

-910N

|

-650N

|

-1750N

|

-1650N

|

-1280N

|

-900N

|

-2040N

|

1910N

|

-1480N

|

-1050N

|

|

1:10 to

1:5 |

-1540N

|

-1450N

|

-1120N

|

-790N

|

-2140N

|

-2020N

|

-1570N

|

-1110N

|

-2490N

|

-2350N

|

-1820N

|

-1290N

|

|

1:5 to

No Limit |

-1850N

|

-1740N

|

-1350N

|

-960N

|

-2580N

|

-2430N

|

-1890N

|

-1330N

|

-3000N

|

-2820N

|

-2190N

|

-1550

|

|

2.47 TIES PER METRE SQUARE REQUIRE 900MM HORIZONTAL CENTRES AND 450MM VERTICAL CENTRES |

|

TIE DENSITY

|

Wind Zone A (44m/s)

|

Wind Zone B (52m/s)

|

Wind Zone C (56m/s)

|

|||||||||

|

4.94m2

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

|

Level to

1:20 |

-500N

|

-470N

|

-360N

|

-260N

|

-700N

|

-660N

|

-510N

|

-360N

|

-810N

|

-760N

|

-600N

|

-420N

|

|

1:20 to

1:10 |

-630N

|

-590N

|

-460N

|

-320N

|

-870N

|

-830N

|

-640N

|

-450N

|

-1020N

|

-960N

|

-740N

|

-520N

|

|

1:10 to

1:5 |

-770N

|

-720N

|

-560N

|

-400N

|

-1070N

|

-1010N

|

-780N

|

-550N

|

-1240N

|

-1180N

|

-900N

|

-640N

|

|

1:5 to

No Limit |

-930N

|

-870N

|

-670N

|

-480N

|

-1300N

|

-1220N

|

-950N

|

-670N

|

-1500N

|

-1410N

|

-1090N

|

-770N

|

| 4.94 TIES PER METRE SQUARE REQUIRE 450MM HORIZONTAL CENTRES AND 450MM VERTICAL CENTRES |

NOTE: You can use other tie densities shown on menu 'Tie Densities'. To do this select tie load for your particular site conditions from one of the above two tables, then multiply your selected tie load by the tie density of that table. This will give you the load per metre squared. Then divide the load per metre squared by any of the tie densities shown in 'Tie Densities'. To get the required tie load for that density, you must then install ties to the required vertical and horizontal spacing centres of the selected tie density.

|

The densities and spacing

|

||

|

Ties per M2

|

Vertical Centres

|

Horizontal Centres

|

|

2.47

|

450mm

|

900mm

|

|

2.96

|

450mm

|

750mm

|

|

3.29

|

450mm

|

675mm

|

|

4.94

|

450mm

|

450mm

|

|

5.92

|

375mm

|

450mm

|

|

7.40

|

300mm

|

450mm

|

|

9.86

|

300mm

|

338mm

|

|

13.12

|

255mm

|

338mm

|

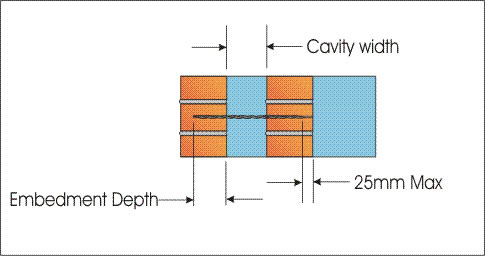

Tie Selection

|

Cavity Range |

Inner Leaf Embedment

70mm

|

|

0mm to 25mm

|

170mm

|

|

25mm to 50mm

|

195mm

|

|

50mm to 75mm

|

220mm

|

|

75mm to 100mm

|

245mm

|

|

100mm to 125mm

|

270mm

|

|

125mm to 150mm

|

295mm

|

Installation Procedure

|

A light hammer drill is recommended I.E. no more than 1.5nm impact and not less than 3000 impacts a minute.

|

|

|

1. Drill a clearance hole through the outer leaf. Make sure to avoid frogs, core holes. Then drill 70mm into the inner leaf 11mm clearance hole for 6mm Tie, 12mm clearance hole for 8mm Tie then check cavity width for tie selection using TABLE A (Tie Selection Tab). |

|

2. Clear outer and inner hole of any brick dust or debris with compressed or air pump. |

|

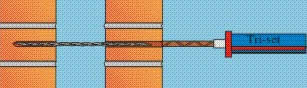

3 Remove plugs and screw on mixing nozzle to Tri-set resin cartridge and place into resin gun, pump resin through mixing nozzle until an even colour is achieved. Then insert nozzle with extension tube through outer clearance hole and across cavity, until just inside the inner clearance hole. Then pump resin until you can fill back pressure of the resin filling hole and pushing extension tube back. Knock off pressure switch and remove nozzle and extension tube. |

|

4 Insert tie by passing through outer clearance hole and across cavity and into resin filled inner clearance hole. |

|

5 Before drilling out all the clearance holes, preliminary load tests should be carried out to establish the strength of inner and outer leaf fixing, which should exceed the required load by 20%. TABLE C (Tie Densities Tab) show's all the required loads for each site taking in consideration wind zones, exposure condition, and topography to a height of 15metres. If due to soft inner or outer leaf material test loads are not exceeding required load by 20% tie density can be increased to reduce the required tie load’s see TABLE C (Tie Densities Tab). 5% of all ties installed must be load tested. |

|

6 Then insert nozzle into clearance hole until touching tie, pump resin around tie, you must get at least 50mm of resin embedded around the tie, then if resin match’s brick bring resin to the surface and make good with a rag. If resin colour dos not match then hold back 6mm and make good with sand/cement and dyes. When working on render surface’s always hold resin back to the surface of brick and make good with sand and cement. |

TRISET PRODUCT DATA SHEET

DESCRIPTION

Triset is a rapid curing 'one shot' two part chemical anchoring cartridge system based on a polyester resin. Applied in one single action to produce a cost effective, tough, chemical resistant fixing. Triset is ideal for close-to edge applications (unlike expansion anchors) as no stress is placed on the surrounding substrate. Versatile in use, Triset is suitable for fixing wall ties, starter bars, studs, bolts or large screws in a wide range of substrates including brickwork, concrete, masonry, stone and PF A blocks. Hollow base materials can be securely fastened into by using Triset in conjunction with a sleeve or sieve.

PREPARATION

1. Drill hole to the correct diameter and depth (see chart for guide), ideally using a rotary percussion machine. For optimum results the hole must be coarse sided. If the holes are produced by diamond drilling the surfaces should be thoroughly roughened.

2. Remove all dust and debris from the hole using a hand air pump or a stiff rotary brush.

3. All bars should be clean and free from oil or grease and all flaking rust should be removed. Threaded rod or struts should be chisel-ended to prevent them being unscrewed from the cured resin.

APPLICATION

1. Attach the mixing nozzle to the cartridge (screw down hand tight).

2. Mount the cartridge into the dispensing gun.

3. Squeeze out material through the nozzle until an even colour is achieved (approximately 5-6 inches of extruded material should be adequate).

4. Apply to the hole working from the base out. Once the required fill is obtained release the pressure and wipe away excess material. Place the bolt or screw into the hole with a rotary action. Wipe away excess material. Attach fixture once resin has cured.

NB Once material has started to extrude through the nozzle, over pressuring the system will not increase flow rate and can cause leakage from the rear of the cartridge.

TECHNICAL DATA

MIXING RATIO 10: 1 by volume

Supplied in 380ml cartridges

| TEMPERATURE | GEL TIME | CURE TIME |

| (C) | (F) | (Minutes) | (Minutes) |

| 5 | 41 | 12 | 240 |

| 10 | 50 | 9 | 180 |

| 15 | 59 | 6 | 150 |

| 20 | 68 | 5 | 120 |

| 25 | 77 | 3 | 60 |

ULTIMATE PHYSICAL PROPERTIES

Tensile Strength (ASTM 638) -> 1ON/mm sq.

Compressive Strength (ASTM 695) -> 78N/mm sq.

Flexural Strength (ASTM 790 - 21N/mm sq.

Elastic Modulus - 4570N/mm sq.

Mixed Density - 1.65g/cm sq.

The above physical properties were arrived at independently by Birmingham City Laboratories.

| ANCHOR SIZE | HOLE DIAMETER | HOLE DEPTH | TENSION | FIXINGS PER UNIT |

| (mm) | (mm) | (mm) | (kN) | (Holes Filled 2 Quarters Full) |

| (Ultimate pull out ) |

380ml |

|||

| 8 | 10 | 80 | 23.7 | 90 |

| 10 | 12 | 90 | 25.7 | 56 |

| 12 | 14 | 110 | 43.3 | 34 |

| 16 | 18 | 125 | 53.7 | 18 |

| 20 | 22 | 150 | 58.3 | 10 |

Tension figures quoted are tested in accordance with BS5080 part 1 in 63 N/mm sq concrete blocks (12 x 12 x 12 inches). In all cases for 16mm and 20mm anchors failure of the concrete block was observed before the anchor was dislodged.

The ultimate pull out strength is varied by:

1. The strength of both the substrate and bar/stud

2. The length of the resin bond to bar

3. Hole preparation

4. Anchor separation

Safety factors of between 2:1 and 4:1 should be considered depending on the strength and nature of the substrate. Due to the inconsistent nature of hollow blocks and bricks tension figures may vary. Site testing should be carried out where necessary to establish particular suitability. In order to achieve maximum performance the distance between the centres of the anchors should be a minimum of2.5 x the embedment depth, and 1.25 x the embedment depth for the minimum distance from edges.

STORAGE

Store in a dry area between 5 C and 25 C. Do not expose to direct sunlight. Storage at higher temperatures will reduce the shelf life.

HEALTH AND SAFETY DATA

Triset contains styrene and is flammable. Do not smoke and do not allow naked flames to come into contact with this material. Avoid breathing vapour and wear suitable protective clothing such as gloves and overalls. On contact with skin wash off immediately with plenty of soap and water.

IMPORTANT

The information and data given is based on our own experience, research and testing and is believed to be reliable and accurate. However, as Wallfast Ltd. cannot know the varied uses to which its products may be applied, or the methods of application used, no warranty as to the fitness or suitability of its products is given or implied. It is the users responsibility to determine suitability of use. For further information, please contact our Technical Department.

MATERIAL SAFETY DATA SHEET

1. IDENTIFICATION OF SUBSTANCE/PREPARATION AND COMPANY

Product Name: TRI-SET POLYESTER RESIN

Company: Wallfast Ltd - Portsmouth - PO3 6FH

Chemical Name & Synonyms: Unsaturated Polyester Resin in Styrene.

For Information: 023 92298443 (8.30am - 4.30pm)

In an Emergency: As above

2. COMPOSITION/INFORMATION OF INGREDIENTS

Hazardous Components: Cas Number Percentage

Styrene 100-42-5 30-50 %

3. HAZARDS IDENTIFICATION

Harmful by inhalation. Irritating to eyes and skin. Flammable.

Signs and Symptoms of Exposure (Acute Effects) Irritant to skin, eyes and respiratory tract.

Signs and Symptoms of Exposure (Possible Long Term Effects). Irritant can cause skin disorders with repeated prolonged exposure. Inhalation of vapour can cause nausea and headaches.

4. FIRST AID MEASURES

Summon immediate medical assistance after

contact with skin, eyes, inhalation or ingestion.

Eye: Irrigate with clean running water for at least 15 minutes. Seek medical attention.

Skin: Remove from skin with plenty of soap and water. Remove contaminated clothing. If irritation persists, seek medical advice.

Ingestion: Drink plenty of water. Seek medical attention. DO NOT INDUCE

VOMITING.

Inhalation: Move patient to fresh air and allow to rest. If patient is slow to recover or unconscious, obtain medical assistance immediately.

First Aiders should protect themselves from exposure (Refer to Section 8)

5. FIRE FIGHTING MEASURES

Extinguishing Media: CO2/ Foam/ Dry Chemical.

Exposure Hazards: Flammable, sealed containers heated can pressurise leading to explosion. Emits acrid black smoke and irritating fumes when heated to decomposition.

Fire Fighting Equipment: N/A

6. ACCIDENTAL RELEASE MEASURES

Do not discharge into sewers. Dike spilled material with liquid absorbent. Scrape or pump into a suitable container. Wash area with water.

Refer to section 5, 8 and 13 for Protective Measures and Disposal.

7. HANDLING AND STORAGE

Store in a cool, dry and well ventilated area. Store away from direct sunlight.

When handling, suitable protective clothing should be worn. (Refer to section 8)

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

OCCUPATIONAL EXPOSURE LIMITS.

Long Term: 100 ppm (UK)

Short Term: 10 minutes 250ppm (UK)

Respiratory: If forced air extraction is not available in enclosed areas an organic vapour mask will be required, if the occupational exposure limit is exceeded.

Ingestion: Unlikely during normal use.

Skin Protection: Wear gloves at all times.

Eye Protection: Not normally required during normal use. If splashing occurs, goggles should be worn.

9. PHYSICAL/CHEMICAL PROPERTIES

Appearance: Amber fluid.

Odour: Styrene.

Viscosity: 6-8 poise at 25 degrees C.

Specific Gravity: 1.10 g/cm3 (20 degrees C)

Boiling Point/Range: N/A

Meeting Point/Melting Range: N/A

Flash Point: 31 degrees C

Flammability: Flammable.

Auto-Flammability: 490 degrees C

Explosive Properties: Lower limit 1.1% Upper limit 6.1%

Oxidising Properties: None.

Vapour Pressure: 6.52 mb 20 C (styrene)

Evaporation Rate: N/A

Solubility: Insoluble in water. Soluble in solvents

pH: N/A

Partition Coefficient: N/A

Di-Electric Strength: N/A

Additional Information: N/A

10. STABILITY AND REACTIVITY

Stability: Can polymerise (solidify) exothermically if heated, exposed to sunlight or by addition of free radical initiators. Stable under normal conditions.

Materials to Avoid: Reacts vigorously with strong oxidising agents and peroxides.

Hazardous Decomposition: Emits acrid smoke and irritating fumes when heated to decomposition.

Hazardous Polymerisations: Polymerisations in a closed container can give rise to pressure, which may rupture the vessel.

11. TOXICOLOGICAL INFORMATION

Oral: Material is classed as harmful. An oral LD50 in rats of 5g/kg Styrene. LC50 in rats ranges between 2770-6000ppm.

Inhalation: Lung irritant can induce drowsiness and eventual unconsciousness.

Eye: Severe irritant

Skin: Moderate irritant

12. ECOLOGICAL INFORMATION

Do not discharge into drains or the environment.

13. DISPOSAL CONSIDERATIONS

In an uncured state, place in a suitable container and dispose as chemical waste in accordance with local regulations. Small quantities may be reacted with the corresponding amount of activator. Allow curing and dispose as solid waste.

14. TRANSPORT INFORMATION

Supply label: Harmful

Flammable

IMDG Code: 3379 UN No./SI No: 1866

EAC: 3 (Y) Hazard Class: 3

ADR HIN: 30 Packing Group: III

15. REGULATORY INFORMATION

Labelling: Harmful, Flammable.

Risk Phrases (R10) Flammable.

(R20) Harmful by inhalation.

(R36/38) Irritating to skin and eyes.

Safety phrases (S2) Keep out of reach of children.

(S23) Do not breathe vapour.

(S36/37/39) Wear suitable protective Clothing.

Gloves and eye/face protection.

16. OTHER INFORMATION

Our ref: SMJH

Date of Preparation: March 2002

Prepared By: S Mullineaux

The information contained within this document is furnished without warranty of any kind. Users should consider this data only as a supplement of other information gathered by them and make independent determinations of suitability and completeness of information from all sources to ensure proper use and disposal of these materials and the safety of employees customers.

To save the file to your computer, right click on the following link and select "save file as..."

www.wallfast.co.uk/pdf/Resi-fix.pdf

5 other products

Viewed products

-

Resi-Fix

Cavity Wall Tie Replacement System -...