No products

Prices are tax excluded

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

View larger

View larger

Tri-Fix

New

IMPORTANT: A Support Tool & Drill Extension is required to install Tri-Fix Wall Ties. Please make sure to add these to your basket from the dropdown menu below. Thank you.

Please view the 'Quantity Discounts' tab below to see our pricing for larger orders.

Volume discounts

| Quantity | Price | You Save |

|---|---|---|

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

| 100 | £ 55.06 | Up to £ 1,835.25 |

| 20 | £ 66.07 | Up to £ 146.82 |

- More info

- Quantity Discounts

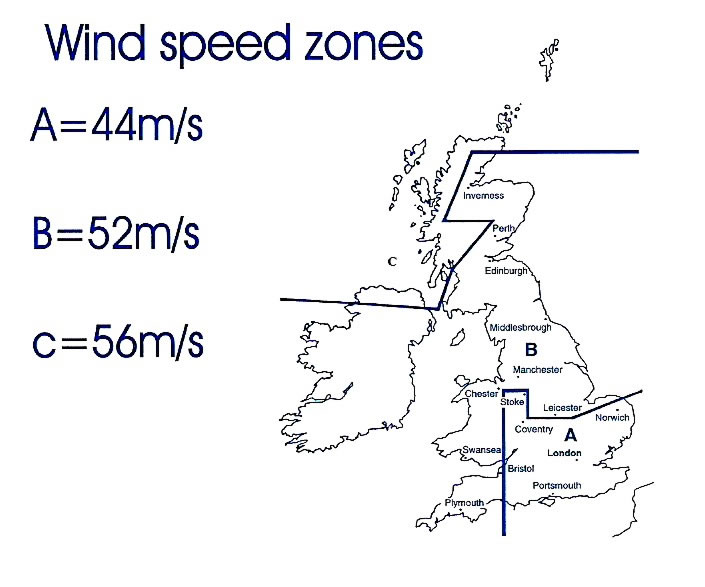

- Wind Zones

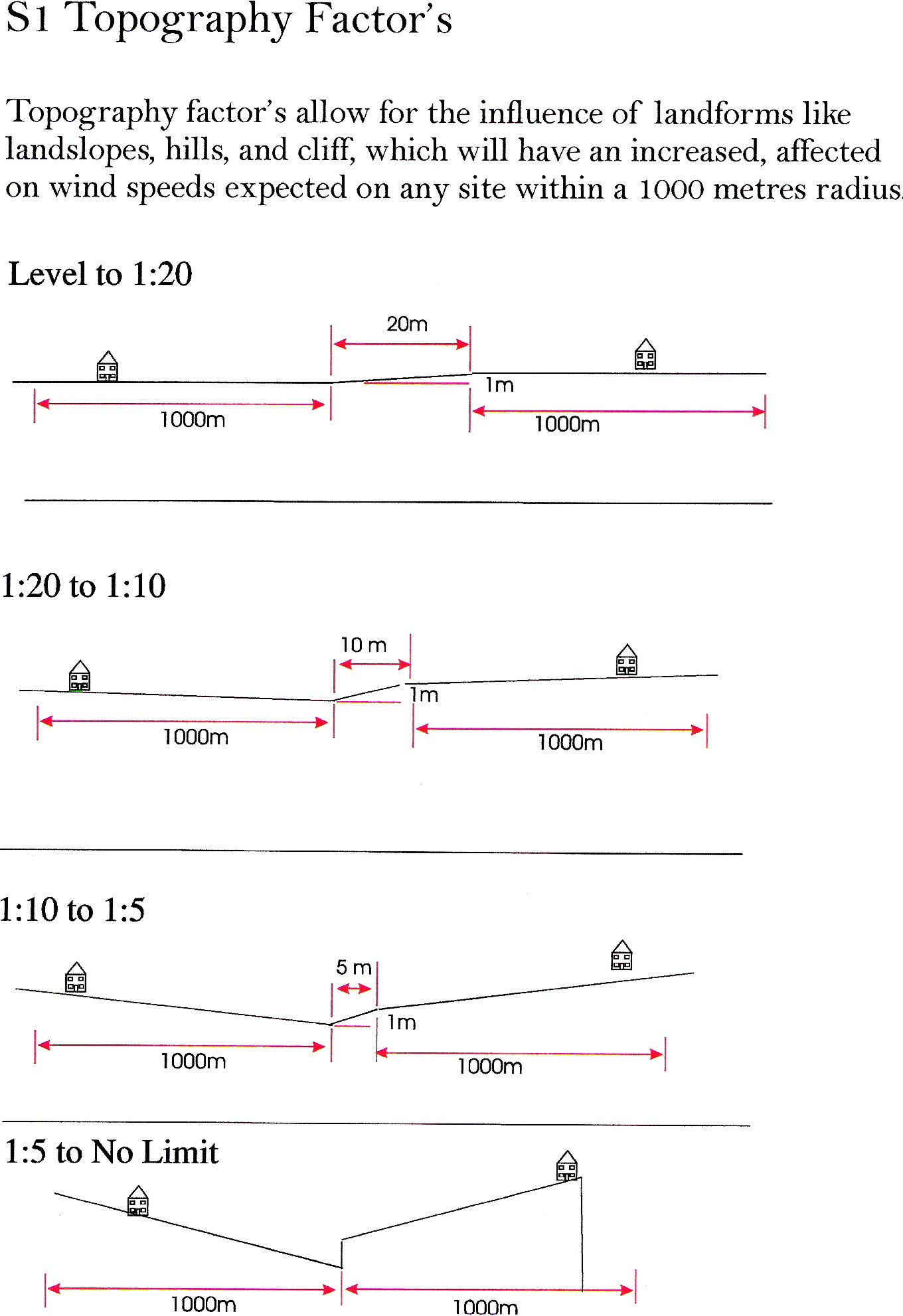

- Topography

- Pilot Drills

- Tie Densities

- Tie Selection

- Tie Spacing

- Installation

- PDF Download

- Related Posts

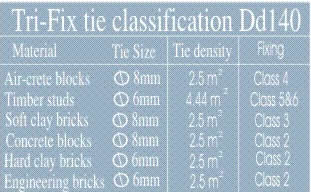

The versatile Tri-fix wall tie replacement system can be used to tie together a large range of differing materials like timber, air-crete blocks, clay bricks, stone, concrete blocks and steel beams

Tri-Fix-Ties are manufactured out of 304 or 316 Stainless Steel and have been independently tested using a common range of building materials by the University of Portsmouth material testing department in accordance with BS 1243 and EN10088. They can be installed quickly and easily by drilling a clearance hole through the outer leaf, then depending on inner leaf material install either a 6mm or 8mm tie via a pilot hole in the inner leaf if required.

Tri-Fix Ties are a stress free fixing allowing them to be installed close to the edge of bricks/blocks and concrete with out causing any splitting or cracking. When being used for tying cavity masonry the constant helix of Tri-Fix Ties gives multi water drips stopping water transfer across cavities.The low cross sectional area of Tri-Fix Ties gives good sound proofing qualities and allows lateral flexibility to over come any misalignment or seasonal thermal movement, while still maintaining the required resistance to wind-loads.

Installation Procedure

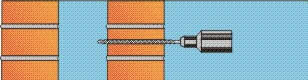

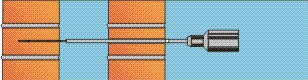

1. Drill clearance hole in outer leaf.

2. If required, drill pilot hole in inner leaf.

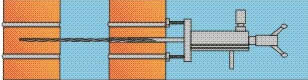

3. Use support tool to drive tie into inner leaf.

4. Load test tie to required site loads.

5. Fill clearance hole with resin to bond tie to outer leaf.

| Size | Buy 20+ | Buy 100+ |

| 100 Tri-Fix Ties 6mm x 170mm | £66.07 | £55.06 |

| 100 Tri-Fix Ties 6mm x 195mm | £70.50 | £58.75 |

| 100 Tri-Fix Ties 6mm x 210mm | £73.34 | £61.12 |

| 100 Tri-Fix Ties 6mm x 220mm | £76.19 | £63.49 |

| 100 Tri-Fix Ties 6mm x 235mm | £79.03 | £65.86 |

| 100 Tri-Fix Ties 6mm x 245mm | £83.00 | £69.17 |

| 100 Tri-Fix Ties 8mm x 170mm | £68.23 | £56.86 |

| 100 Tri-Fix Ties 8mm x 195mm | £73.91 | £61.59 |

| 100 Tri-Fix Ties 8mm x 210mm | £76.76 | £63.97 |

| 100 Tri-Fix Ties 8mm x 220mm | £79.62 | £66.35 |

| 100 Tri-Fix Ties 8mm x 235mm | £82.47 | £68.73 |

| 100 Tri-Fix Ties 8mm x 245mm | £85.29 | £71.07 |

| 100 Tri-Fix Ties 8mm x 260mm | £88.16 | £73.46 |

| 100 Tri-Fix Ties 8mm x 270mm | £90.98 | £75.82 |

| 100 Tri-Fix Ties 8mm x 285mm | £93.85 | £78.21 |

| 100 Tri-Fix Ties 8mm x 295mm | £96.65 | £80.54 |

| 100 Tri-Fix Ties 8mm x 320mm | £102.34 | £85.28 |

Tie Diameter, Embedment Depth& Drill Selection

|

Material

|

N/mm2

|

Tie Diameter

|

Minimum embedment depth

|

Pilot hole drill diameter

|

Clearance hole drill diameter

|

| Air Crete block |

2.8

|

8mm

|

90mm

|

N/A

|

12mm

|

| Leca block |

3.5

|

8mm

|

70mm

|

N/A

|

12mm

|

| Concrete block |

7.0

|

8mm

|

70mm

|

4.5mm

|

12mm

|

| Old soft brick |

< 5.0

|

8mm

|

70mm

|

4.5mm

|

12mm

|

| Old med brick |

> 5.0

|

6mm

|

70mm

|

4.5mm

|

12mm

|

| Most modern bricks |

> 11.0

|

6mm

|

70mm

|

4.5mm

|

10mm

|

| Semi engineering bricks |

30.0

|

6mm

|

50mm

|

4.5mm

|

10mm

|

| Softwood |

Sc3

|

6mm

|

50mm

|

N/A

|

10mm

|

TIE LOADS & DENSITIES

| S2 Ground roughness, building size and height above ground factor worse case class A, HEIGHT 15 METRES. | |

|

I |

Open country with no windbreaks and seafronts |

| II | Open country with scattered windbreaks |

| III | Suburban country with many wind breaks; small towns, out skirts of large cities |

| IV |

Urban surface with large and frequent obstructions, i.e. City centres |

|

Tie loads for different site conditions

|

||||||||||||

|

TIE DENSITY

|

Wind Zone A (44m/s)

|

Wind Zone B (52m/s)

|

Wind Zone C (56m/s)

|

|||||||||

|

2.47m2

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

|

Level to

1:20 |

-1000N

|

-940N

|

-730N

|

-520N

|

-1400N

|

-1320N

|

-1020N

|

-720N

|

-1620N

|

-1520N

|

-1180N

|

-840N

|

|

1:20 to

1:10 |

-1260N

|

-1180N

|

-910N

|

-650N

|

-1750N

|

-1650N

|

-1280N

|

-900N

|

-2040N

|

1910N

|

-1480N

|

-1050N

|

|

1:10 to

1:5 |

-1540N

|

-1450N

|

-1120N

|

-790N

|

-2140N

|

-2020N

|

-1570N

|

-1110N

|

-2490N

|

-2350N

|

-1820N

|

-1290N

|

|

1:5 to

No Limit |

-1850N

|

-1740N

|

-1350N

|

-960N

|

-2580N

|

-2430N

|

-1890N

|

-1330N

|

-3000N

|

-2820N

|

-2190N

|

-1550

|

|

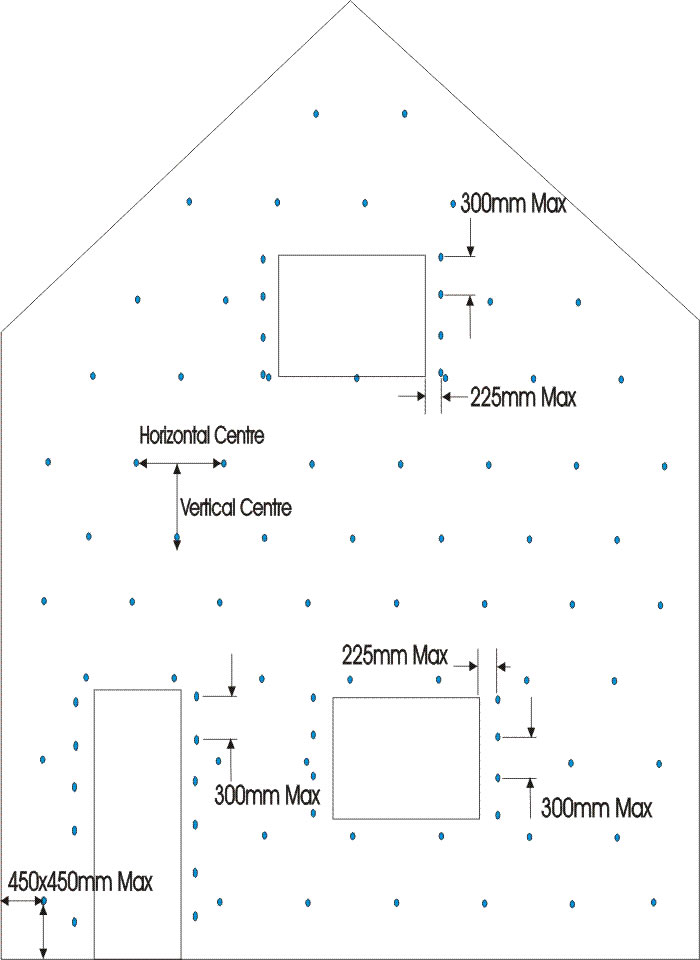

2.47 TIES PER METRE SQUARE REQUIRE 900MM HORIZONTAL CENTRES AND 450MM VERTICAL CENTRES |

|

TIE DENSITY

|

Wind Zone A (44m/s)

|

Wind Zone B (52m/s)

|

Wind Zone C (56m/s)

|

|||||||||

|

4.94m2

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

|

Level to

1:20 |

-500N

|

-470N

|

-360N

|

-260N

|

-700N

|

-660N

|

-510N

|

-360N

|

-810N

|

-760N

|

-600N

|

-420N

|

|

1:20 to

1:10 |

-630N

|

-590N

|

-460N

|

-320N

|

-870N

|

-830N

|

-640N

|

-450N

|

-1020N

|

-960N

|

-740N

|

-520N

|

|

1:10 to

1:5 |

-770N

|

-720N

|

-560N

|

-400N

|

-1070N

|

-1010N

|

-780N

|

-550N

|

-1240N

|

-1180N

|

-900N

|

-640N

|

|

1:5 to

No Limit |

-930N

|

-870N

|

-670N

|

-480N

|

-1300N

|

-1220N

|

-950N

|

-670N

|

-1500N

|

-1410N

|

-1090N

|

-770N

|

| 4.94 TIES PER METRE SQUARE REQUIRE 450MM HORIZONTAL CENTRES AND 450MM VERTICAL CENTRES |

NOTE: You can use other tie densities shown on menu 'Tie Densities'. To do this select tie load for your particular site conditions from one of the above two tables, then multiply your selected tie load by the tie density of that table. This will give you the load per metre squared. Then divide the load per metre squared by any of the tie densities shown in 'Tie Densities'. To get the required tie load for that density, you must then install ties to the required vertical and horizontal spacing centres of the selected tie density.

|

The densities and spacing

|

||

|

Ties per M2

|

Vertical Centres

|

Horizontal Centres

|

|

2.47

|

450mm

|

900mm

|

|

2.96

|

450mm

|

750mm

|

|

3.29

|

450mm

|

675mm

|

|

4.94

|

450mm

|

450mm

|

|

5.92

|

375mm

|

450mm

|

|

7.40

|

300mm

|

450mm

|

|

9.86

|

300mm

|

338mm

|

|

13.12

|

255mm

|

338mm

|

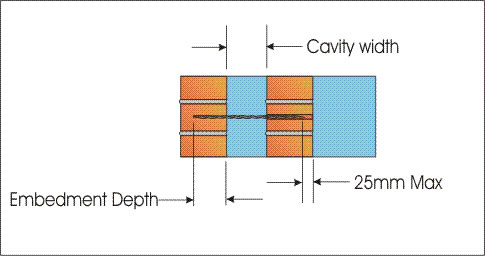

Tie Selection

|

Inner Leaf Embedment

|

|||

|

Cavity Range

|

50mm

|

70mm

|

90mm

|

|

25mm to 50mm

|

170mm

|

195mm

|

220mm

|

|

50mm to 75mm

|

195mm

|

220mm

|

245mm

|

|

75mm to 100mm

|

220mm

|

245mm

|

270mm

|

|

100mm to 125mm

|

245mm

|

270mm

|

295mm

|

|

125mm to 150mm

|

270mm

|

295mm

|

320mm

|

|

A light hammer drill is recommended I.E. no more than 1.5nm impact and not less than 3000 impacts a minute.

|

|

|

1 Drill a clearance hole though the outer leaf making sure to avoid frogs and core holes. 10mm clearance hole for a 6mm tie, 12mm clearance hole for a 8mm tie. Then check cavity width and inner leaf material for tie selection using TABLES A (Tie Selection Tab) & B (Pilot Drills Tab). |

|

2 The need for a pilot hole will depend on the inner leaf material see TABLE B (Pilot Drills Tab). The pilot drill and drill extension should be passed through the clearance hole until it's touching the inner leaf, then measure back the embedment depth from the face of the outer leaf, and mark by tapping drill extension. Drill into the inner leaf until the tape is level with outer leaf, then let the drill slow down before removing drill extension to prevent pilot drill breaking against side of clearance hole. |

|

3 Place the selected tie into the appropriate support tool. The support tool and the tie should be passed through the clearance until the tie is touching the inner leaf, then measure back the embedment depth from the face of the outer leaf, and mark by tapping, then hammer the tie in until the tape is level with the outer leaf, let the drill slow down and remove the support tool. Check that the tie is no deeper 35mm from the outer surface of the outer leaf or a longer tie will be needed. |

|

4 Before drilling out the clearance holes, preliminary load test should be carried out to establish the strength of inner and outer leaf fixing, which should exceed the required load by 20%, TABLE E shows all the required loads f

or each site taken in consideration wind zones, exposure condition and topography to a height 15 meters, if due to soft inner or outer leaf material test loads are not exceeding required load by 20%. Tie density can be increased to reduce the required tie loads see TABLE D (Tie Densities Tab) tie densities and spacing. 5% of all ties installed must be load tested. |

|

5 Clear clearance hole of any brick dust or debris with compressed or air pump. |

|

6 Remove plugs and screw on mixing nozzle to Tri-set resin cartridge and place into resin gun, pump resin through mixing nozzle until an even colour is achieved. Then insert nozzle into clearance hole until touching tie, pump resin around tie, you must get at least 50mm of resin embedded around the tie, then if resin matches brick bring resin to the surface and make good with a rag, if resin colour fails to match then hold back 6mm and make good with sand/cement and dyes. When working on rendered surfaces always hold resin back to brick/block and make good with sand and cement. |

To save the file to your computer, right click on the following link and select "save file as..."

www.wallfast.co.uk/pdf/Tri-fix.pdf

5 other products

Viewed products

-

Tri-Fix

Used to tie a large range of...