No products

Prices are tax excluded

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

View larger

View larger

Fast-Fix

New

Note: Please remember to purchase an install tool and drill bit from the dropdown menu.

(Selectable from Sizes Dropdown Menu Below)

Fast-Fix Install Kit Small (£89)

20m2 kit based on spacing of 2.5 ties per m2:

- 50 X 8mm x 220mm Fast-Fix Ties

- Fast-Fix SDS Install Tool

- 5.5mm x 310mm SDS Drill Bit

Fast-Fix Install Kit Large (£129)

40m2 kit based on spacing of 2.5 ties per m2:

- 100 X 8mm x 220mm Fast-Fix Ties

- Fast-Fix SDS Install Tool

- 5.5mm x 310mm SDS Drill Bit

Please view the 'Quantity Discounts' tab below to see our pricing for larger orders.

Volume discounts

| Quantity | Price | You Save |

|---|---|---|

| 20 | £ 68.23 | Up to £ 151.62 |

| 10 | £ 72.02 | Up to £ 37.91 |

| 20 | £ 68.23 | Up to £ 151.62 |

| 10 | £ 72.02 | Up to £ 37.91 |

| 20 | £ 68.23 | Up to £ 151.62 |

| 10 | £ 72.02 | Up to £ 37.91 |

| 10 | £ 72.02 | Up to £ 37.91 |

| 20 | £ 68.23 | Up to £ 151.62 |

| 10 | £ 72.02 | Up to £ 37.91 |

| 20 | £ 68.23 | Up to £ 151.62 |

| 10 | £ 72.02 | Up to £ 37.91 |

- More info

- Quantity Discounts

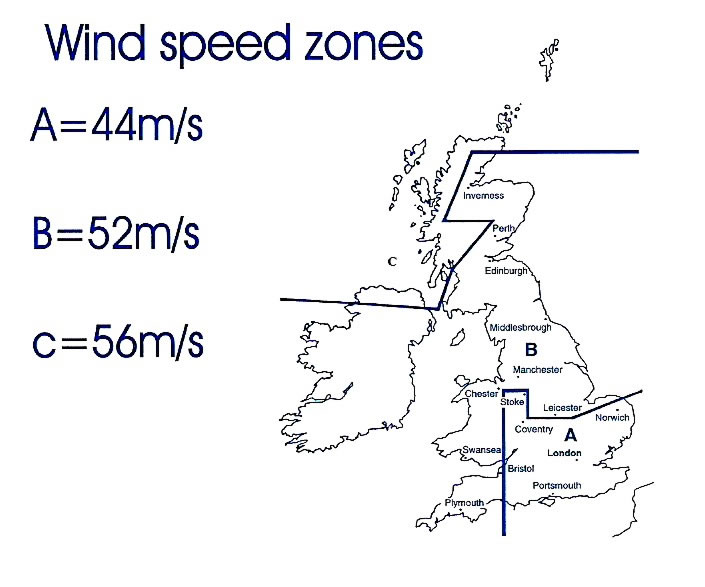

- Wind Zones

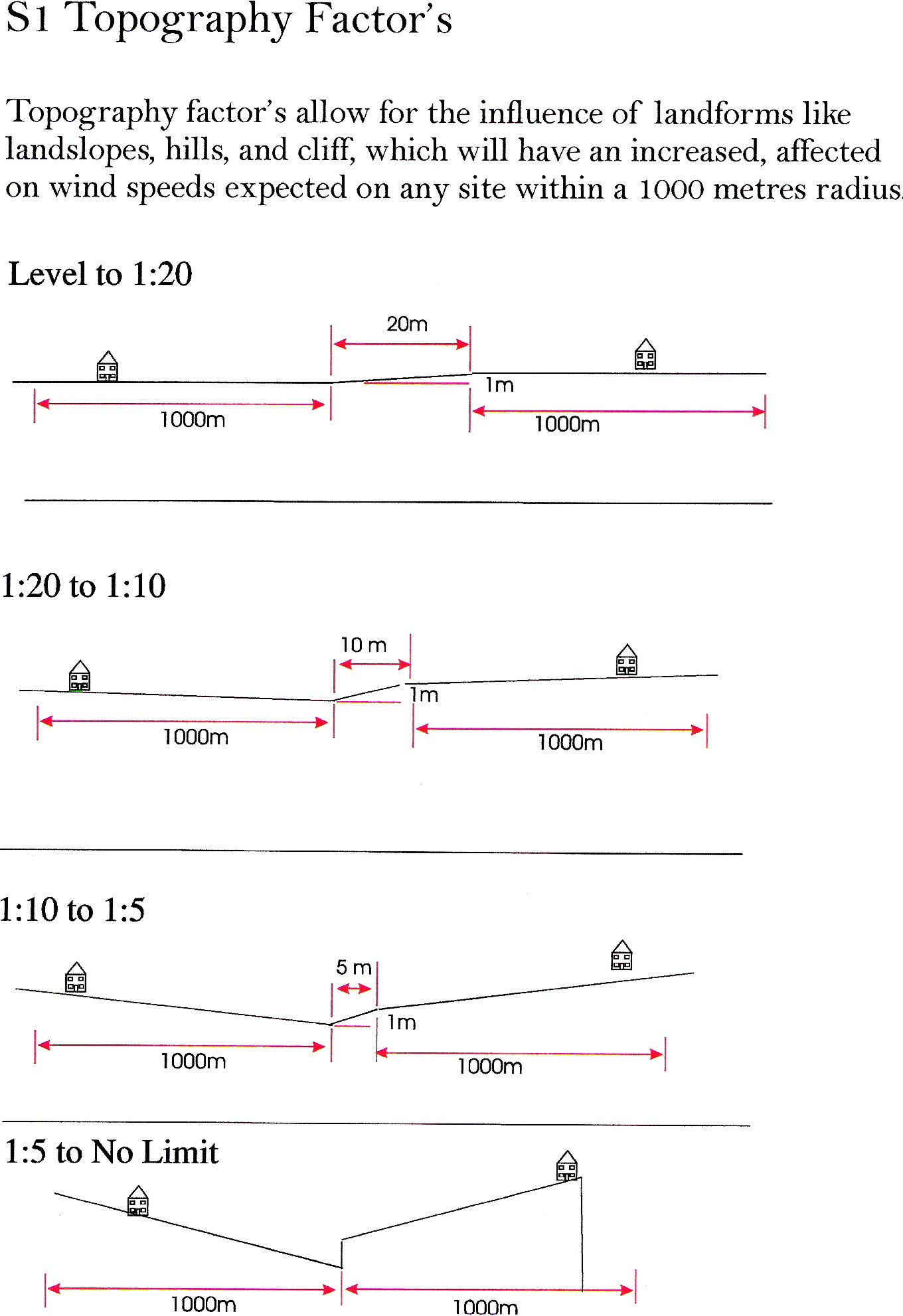

- Topography

- Pilot Drills

- Tie Densities

- Tie Selection

- Tie Spacing

- PDF Download

- Related Posts

Fast-Fix

Fast-fix wall tie replacement and masonry repair system can be used to re-tie and repair a wide range of differing materials like air-crete blocks, clay bricks, stone and concrete blocks.

Benefits & Features

- Quick installation. Just drill and drive.

- Low labour costs.

- High tensile strength.

- Allows for thermal movement.

- Multi water drips.

- Easily installed through cavity insulation.

- Designed and tested to EN10088.

- Insurance backed guarantees.

- Austentic 304 or 316 stainless steel.

- Effective in tying cavity and solid walls.

- No mechanical expansion problems.

- No resin, no rubber, high fire rating.

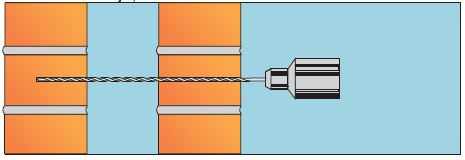

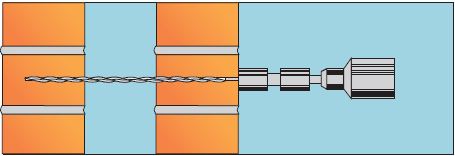

Adding Wall Ties

1. Drill pilot hole through outer leaf and then continue pilot hole if required, until recommended depth in inner leaf is reached.

2. Insert tie into Fast-Fix tool, then position front of tie into pilot hole and drive home.

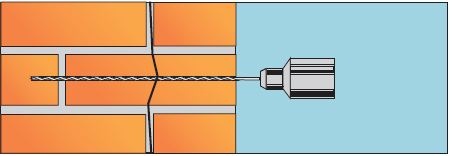

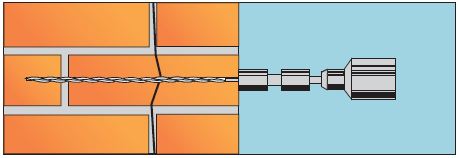

Masonry Crack Repair

1. Drill pilot hole through masonry until recommended depth is reached.

2. Insert tie into Fast Fix tool, then position front of tie into pilot hole and drive home.

| Size | Buy 10+ | Buy 20+ |

| 100 Fast Fix Ties 8mm x 170mm | £72.02 | £68.23 |

| 100 Fast Fix Ties 8mm x 195mm | £78.02 | £73.91 |

| 100 Fast Fix Ties 8mm x 220mm | £84.04 | £79.62 |

| 100 Fast Fix Ties 8mm x 245mm | £90.02 | £85.29 |

| 100 Fast Fix Ties 8mm x 270mm | £96.03 | £90.98 |

| 100 Fast Fix Ties 8mm x 295mm | £102.02 | £96.55 |

Pilot Drill & Embedment Depth Selection

|

Material

|

N/mm2

|

Tie Size

|

Minimum embedment depth

|

Pilot hole diameter

|

| Air Crete block |

2.8

|

8mm

|

90mm

|

N/A

|

| Leca block |

3.5

|

8mm

|

70mm

|

N/A

|

| Concrete block |

7.0

|

8mm

|

70mm

|

5.5mm

|

| Old soft brick |

< 5.0

|

8mm

|

70mm

|

5.0mm

|

| Old med brick |

> 5.0

|

8mm

|

70mm

|

5.0mm

|

| Most modern bricks |

> 11.0

|

8mm

|

70mm

|

5.5mm

|

| Semi engineering bricks |

30.0

|

8mm

|

50mm

|

6mm

|

Tie Loads & Densities

| S2 Ground roughness, building size and height above ground factor worse case class A, HEIGHT 15 METRES. | |

|

I |

Open country with no windbreaks and seafronts |

| II | Open country with scattered windbreaks |

| III | Suburban country with many wind breaks; small towns, out skirts of large cities |

| IV |

Urban surface with large and frequent obstructions, i.e. City centres |

|

Tie loads for different site conditions

|

||||||||||||

|

TIE DENSITY

|

Wind Zone A (44m/s)

|

Wind Zone B (52m/s)

|

Wind Zone C (56m/s)

|

|||||||||

|

2.47m2

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

|

Level to

1:20 |

-1000N

|

-940N

|

-730N

|

-520N

|

-1400N

|

-1320N

|

-1020N

|

-720N

|

-1620N

|

-1520N

|

-1180N

|

-840N

|

|

1:20 to

1:10 |

-1260N

|

-1180N

|

-910N

|

-650N

|

-1750N

|

-1650N

|

-1280N

|

-900N

|

-2040N

|

1910N

|

-1480N

|

-1050N

|

|

1:10 to

1:5 |

-1540N

|

-1450N

|

-1120N

|

-790N

|

-2140N

|

-2020N

|

-1570N

|

-1110N

|

-2490N

|

-2350N

|

-1820N

|

-1290N

|

|

1:5 to

No Limit |

-1850N

|

-1740N

|

-1350N

|

-960N

|

-2580N

|

-2430N

|

-1890N

|

-1330N

|

-3000N

|

-2820N

|

-2190N

|

-1550

|

|

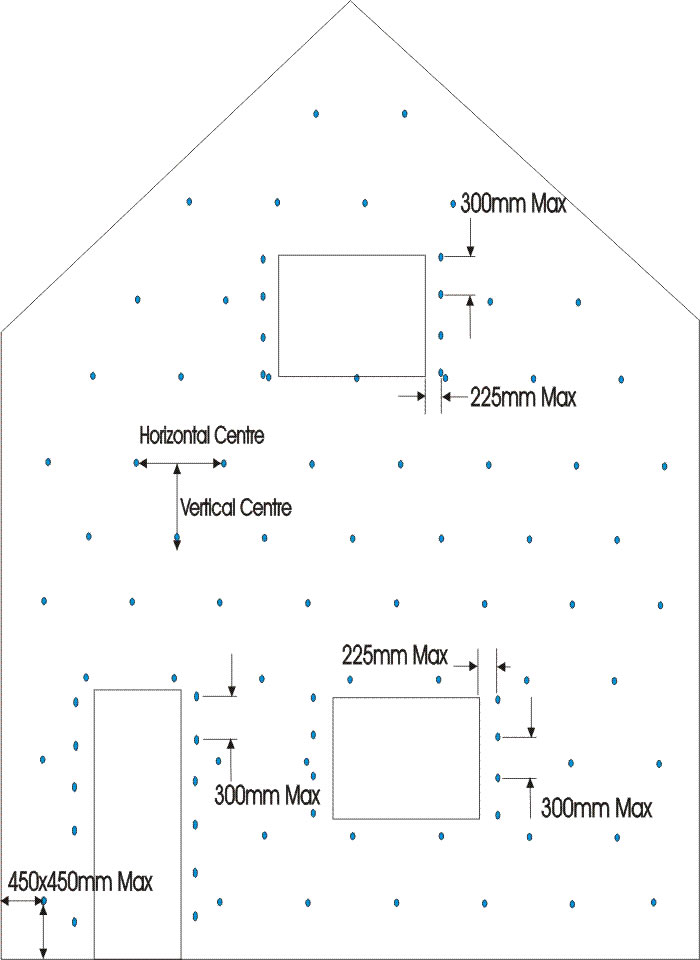

2.47 TIES PER METRE SQUARE REQUIRE 900MM HORIZONTAL CENTRES AND 450MM VERTICAL CENTRES |

|

TIE DENSITY

|

Wind Zone A (44m/s)

|

Wind Zone B (52m/s)

|

Wind Zone C (56m/s)

|

|||||||||

|

4.94m2

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

I

|

II

|

III

|

IV

|

|

Level to

1:20 |

-500N

|

-470N

|

-360N

|

-260N

|

-700N

|

-660N

|

-510N

|

-360N

|

-810N

|

-760N

|

-600N

|

-420N

|

|

1:20 to

1:10 |

-630N

|

-590N

|

-460N

|

-320N

|

-870N

|

-830N

|

-640N

|

-450N

|

-1020N

|

-960N

|

-740N

|

-520N

|

|

1:10 to

1:5 |

-770N

|

-720N

|

-560N

|

-400N

|

-1070N

|

-1010N

|

-780N

|

-550N

|

-1240N

|

-1180N

|

-900N

|

-640N

|

|

1:5 to

No Limit |

-930N

|

-870N

|

-670N

|

-480N

|

-1300N

|

-1220N

|

-950N

|

-670N

|

-1500N

|

-1410N

|

-1090N

|

-770N

|

| 4.94 TIES PER METRE SQUARE REQUIRE 450MM HORIZONTAL CENTRES AND 450MM VERTICAL CENTRES |

NOTE: You can use other tie densities shown on menu 'Tie Densities'. To do this select tie load for your particular site conditions from one of the above two tables, then multiply your selected tie load by the tie density of that table. This will give you the load per metre squared. Then divide the load per metre squared by any of the tie densities shown in 'Tie Densities'. To get the required tie load for that density, you must then install ties to the required vertical and horizontal spacing centres of the selected tie density.

|

The densities and spacing

|

||

|

Ties per M2

|

Vertical Centres

|

Horizontal Centres

|

|

2.47

|

450mm

|

900mm

|

|

2.96

|

450mm

|

750mm

|

|

3.29

|

450mm

|

675mm

|

|

4.94

|

450mm

|

450mm

|

|

5.92

|

375mm

|

450mm

|

|

7.40

|

300mm

|

450mm

|

|

9.86

|

300mm

|

338mm

|

|

13.12

|

255mm

|

338mm

|

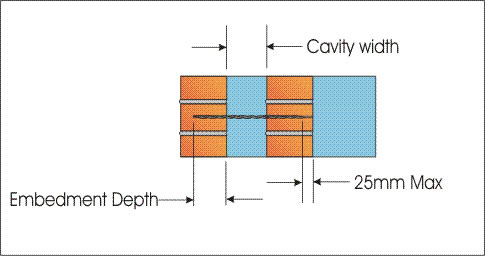

Tie Selection

|

Inner Leaf Embedment

|

|||

|

Cavity Range

|

50mm

|

70mm

|

90mm

|

|

25mm to 50mm

|

170mm

|

195mm

|

220mm

|

|

50mm to 75mm

|

195mm

|

220mm

|

245mm

|

|

75mm to 100mm

|

220mm

|

245mm

|

270mm

|

|

100mm to 125mm

|

245mm

|

270mm

|

295mm

|

|

125mm to 150mm

|

270mm

|

295mm

|

320mm

|

To save the file to your computer, right click on the following link and select "save file as..."

www.wallfast.co.uk/pdf/Fast-fix.pdf

3 other products

Viewed products

-

Fast-Fix

Easy to use professional wall tie...